ROQ Laser acquires 3D scanner with the highest precision on the market

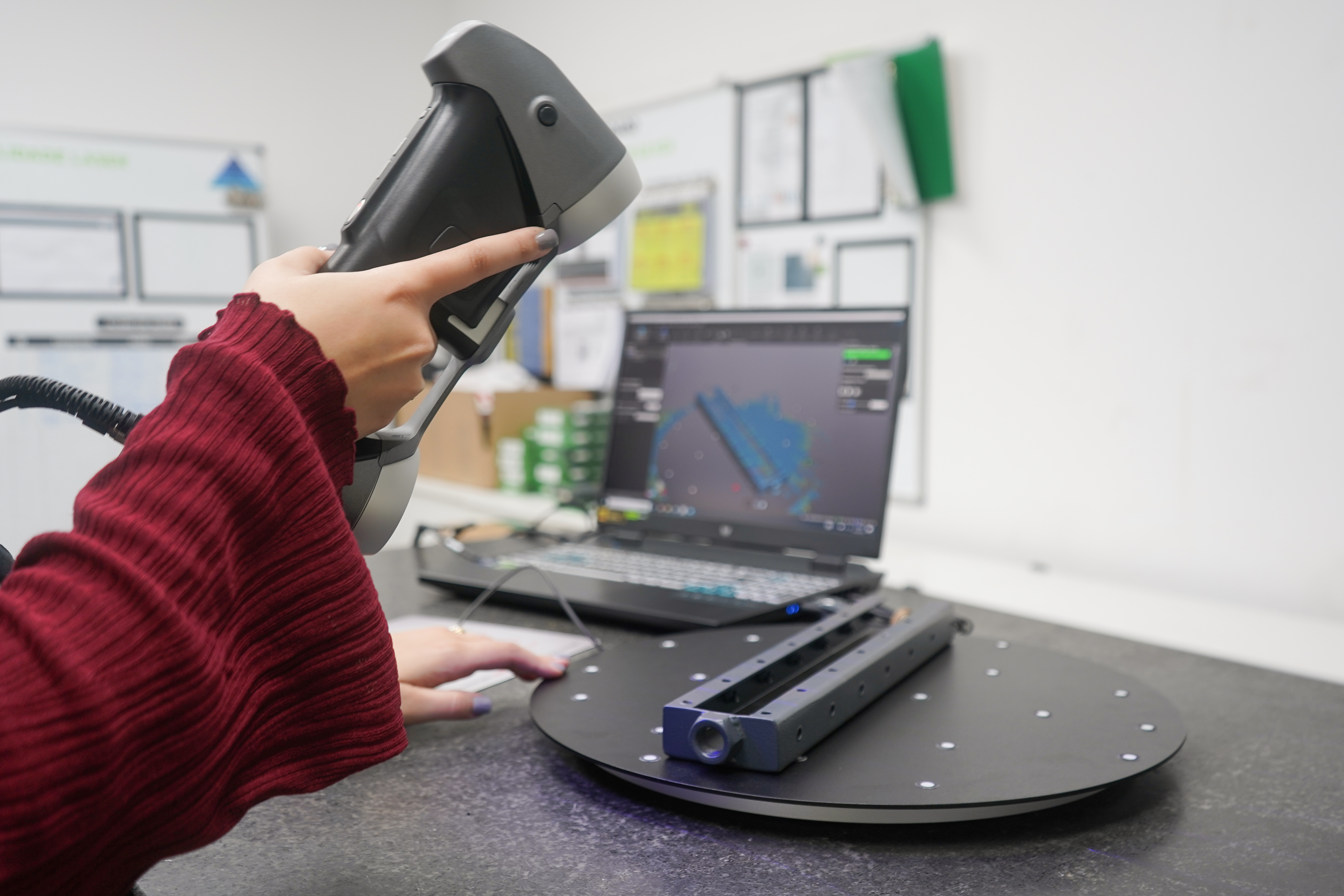

To improve the production and quality control process, ROQ Laser recently acquired a 3D scanner.

With the acquisition of this new equipment, our company is investing even more in quality and at the same time improving its production processes and checking that the parts and structures produced comply with its customers' specifications.

Commitment to guaranteeing the quality of what we produce at ROQ Laser

ROQ Laser has invested in more capable and faster control and measurement systems.

To improve all processes, the Quality Department has been continuously professionalizing itself, which is reflected in the acquisition of equipment that allows for more accurate and effective control.

The result of this is the acquisition of three-dimensional measuring machines: the Measuring Arm and this new 3D Scanner.

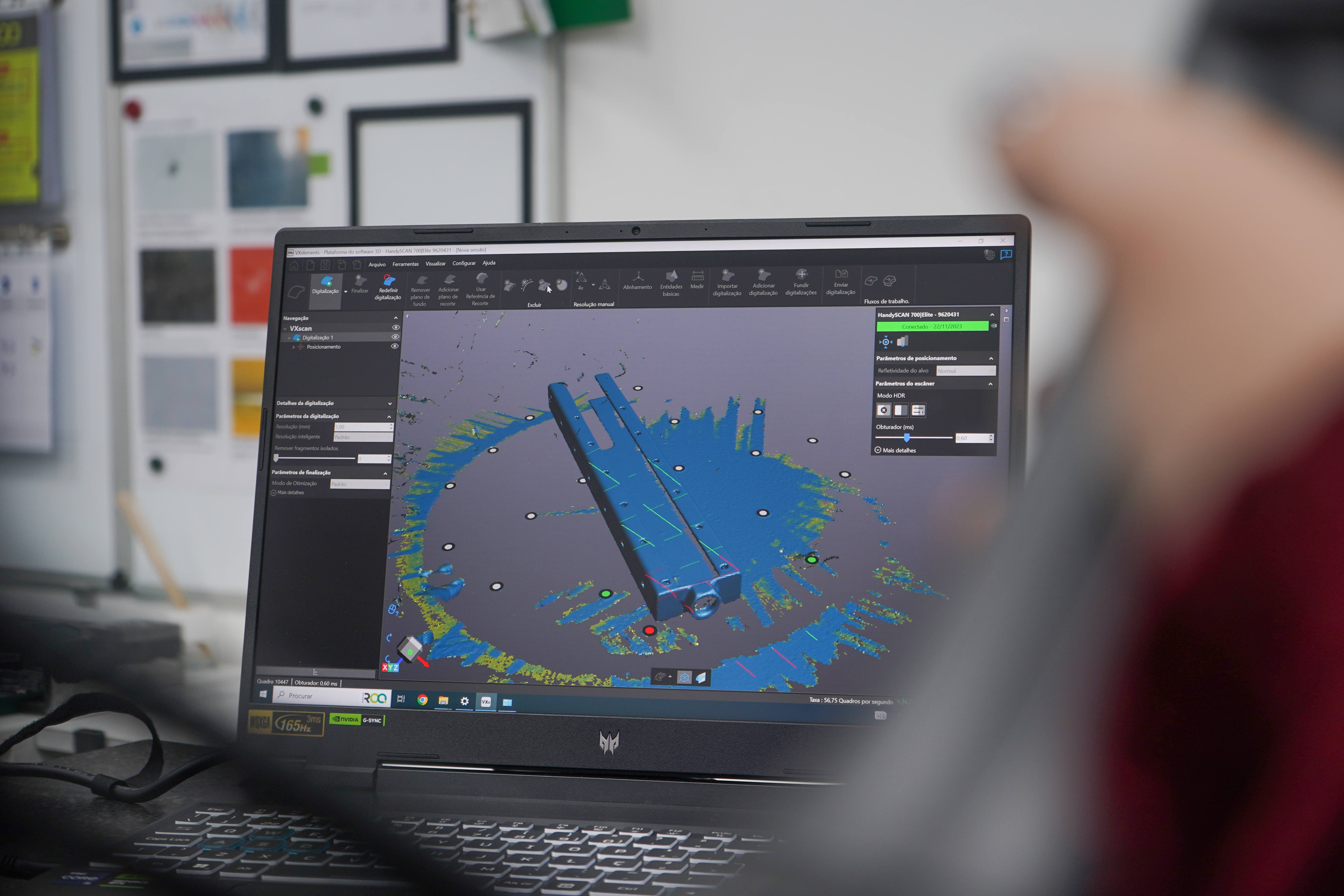

The use of this equipment in the validation of new or existing products allows for the collection of more and better data and assists in improvements and new developments.

Features of this equipment that ROQ Laser owns and uses daily:

- Top technology

- Accuracy and precision

- Portability

- Versatility

- Speed

- Reduced human error

- More precise control

- Product conformity

- Reverse engineering

What are the main specifications of ROQ Laser's new 3D scanner?

The 3D scanner purchased was produced by a leading company in portable 3D measurement technologies.

This solution combines high-performance 3D scanning with new multiple blue laser technology.

Its ergonomic and portable design sets the standard for measuring all types of parts, regardless of size, material, or complexity, anywhere and in seconds.

The scanning area features 11 crossed-blue lasers, generating up to 1,300,000 measurements per second for a fast workflow.

Here's how we use the 3D scanner daily